Dryer Safety – Explosion Protection

- Posted on 19th April 2019

- in Dryer Safety, Dryers

- by John Real

More and more, the safety around spray drying systems is becoming a paramount concern to producers of all kinds. With the release of the NFPA 652 Standard on Fundamentals of Combustible Dust and the requirements for performing Dust Hazard Analysis on dust-producing facilities, the focus on the safety of these facilities is increasingly coming to the forefront of both greenfield projects as well as retrofitting of legacy assets.

More and more, the safety around spray drying systems is becoming a paramount concern to producers of all kinds. With the release of the NFPA 652 Standard on Fundamentals of Combustible Dust and the requirements for performing Dust Hazard Analysis on dust-producing facilities, the focus on the safety of these facilities is increasingly coming to the forefront of both greenfield projects as well as retrofitting of legacy assets.

Powders of almost any kind can form an explosible mixture when dispersed at a sufficient concentration in the air. This makes the explosion protection system a critical plant and life safety system integral to safe operations of any spray drying system. The powder to be produced on a spray drying system should be tested to determine the deflagration characteristics as the first step to designing the explosion protection system. All products should be tested for the following characteristics as these will form the basis of the explosion protection system.

• Pmax – Maximum pressure produced during deflagration. Pressures of less than two (2) psi can destroy a building.

• dP/dtmax – Maximum Rate of Pressure Increase. Maximum rate of pressure rise produced during the deflagration. Value of dP/dt can be used with the vessel volume to determine the value of deflagration index (Kst).

• Kst – Dust Deflagration Index. Maximum rate of pressure increase normalized to the volume in which the rate was measured. Used to measure relative explosive severity compared to other dusts.

• Minimum Explosible Concentration (MEC) – Minimum amount of dust, dispersed in air, required to support a deflagration.

• Minimum Ignition Energy (MIE) – Minimum energy required to ignite. Lowest capacitive spark energy capable of igniting the most ignition-sensitive concentration of a combustible duct-air mixture.

• Limited Oxygen (Oxidant) Concentration (LOC) – The least amount of oxygen required for explosion propagation through the dust cloud.

• Electrostatic Charging Tendency (ECT) – Predicts the likelihood of a material to develop and discharge sufficient static electricity to ignite a dispersed dust cloud.

• Pred – Reduced pressure developed by an explosion event after interception by the explosion protection system.

In general, reducing the particle size of powders leads to an increased Dust Deflagration Index (Kst), increased Maximum Pressure generated (Pmax), and increased Maximum Rate of Pressure Increase (dP/dtmax) while also decreasing the Minimum Explosible Concentration (MEC), decreasing the Minimum Ignition Energy (MIE), and possibly decreasing the Auto-Ignition Temperature (AIT) – the lowest temperature at which the material spontaneously ignites in normal atmosphere without an external source of ignition, such as a flame or spark.

Powders are groups into one of three hazard classes based on the Kst value of the material. Class St-1 materials are those materials with a Kst of less than 200. These materials produce the lowest rates of pressure increase and have the potential for the least structural damage. Class St-2 materials are those materials with a Kst of between 200 and 300 and have moderately high rates of pressure increase and have the potential to produce substantial structural damage. Class St-3 materials have Kst values of more than 300 and have extremely high rates of pressure increase and have the potential to produce the highest levels of structural damage. It is important to keep in mind that materials with a low Kst can have a very high Pmax – meaning that the pressure wave can propagate slowly but produce pressures much greater than a material with a higher Kst but a lower Pmax value.

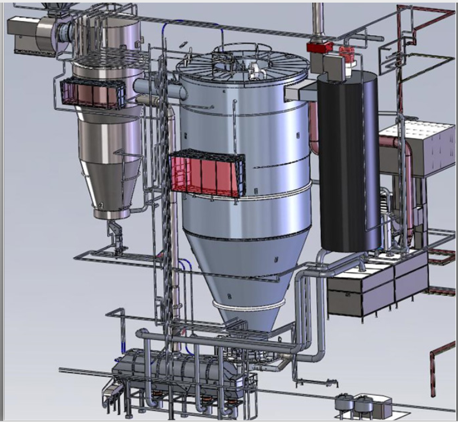

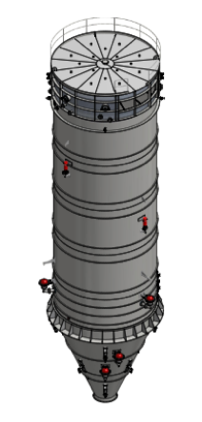

The spray drying system major components are protected from explosions in one of two ways. The major equipment is either equipped with suppression or venting provisions (or potentially both) to either intercept the pressure wave and reduce it to a manageable level or to allow the pressure wave a path to escape the system and be directed into a safe route out of the system. The reduction in pressure achieved by the explosion protection system (Pred) will be the base calculation point for the strength of the equipment. The equipment should be designed to withstand the Pred value without deformation.

Figure 2. Spray Drying System with Venting

Figure 3. Spray Dryer Chamber with Suppression

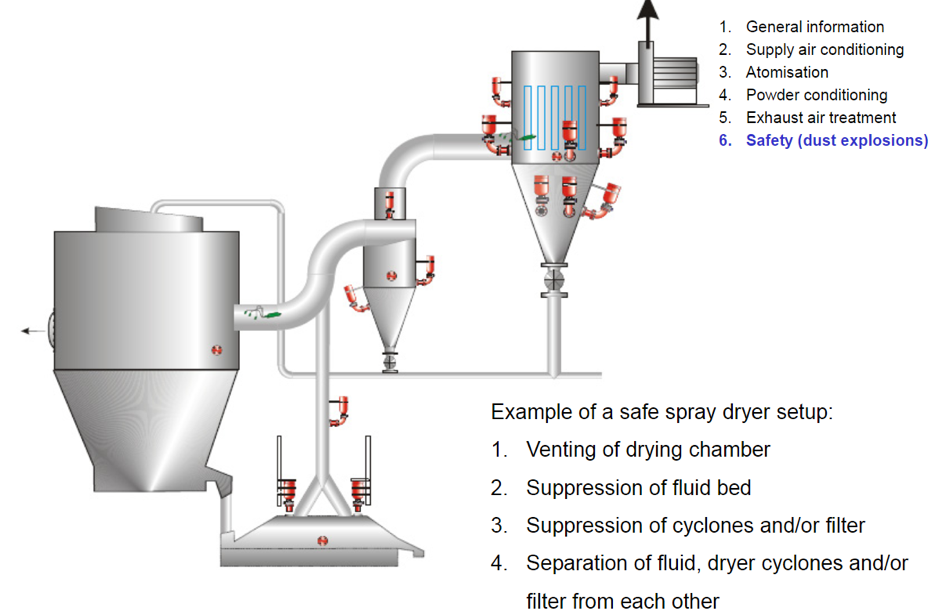

In addition to the explosion venting and/or suppression components on the major equipment, the interconnecting ductwork should also be protected against propagation of a deflagration event by the use of a chemical isolation barrier. The chemical isolation system utilizes the same components as the explosion suppression system. These bottles prevent the propagation of a deflagration event from one piece of major equipment to the other in two ways. First, they prevent a flash fire from passing through the ductwork from one major system component to another. Additionally, they prevent the pressure wave from traveling from one major system component to another which could cause a much more dangerous secondary explosion following the first event.

In addition to the chemical isolation of the interconnecting ductwork, the powder conveying system should be separated from the dryer system through the use of rotary airlock valves or flapper valves. These valves will serve a dual purpose – they will allow consistent dosing of dry powder into the powder conveyance system and they will prevent the propagation of a flash fire or pressure wave from the major dryer components into the powder conveying system. The powder conveying system may also be equipped with its own explosion protections and isolation if deemed necessary.

Figure 4. Example of an Explosion Safe Dryer Configuration

The venting system consists of burst panels which will be installed in specially designed frames. In the event of an explosion, these panels will automatically be forced out of their frames by the pressure wave of the explosion and this will create a pathway for the explosion to exit the vessel. The vent panel must be ducted to an outside wall on the building and should not be facing any other buildings, over top of any other building, walkways, drives, or parking lots and should be pointed in a safe direction.

Figure 5. Burst Panels (Photo Courtesy IEP Technologies)

Figure 6. Burst Panel on Dust Collector (Photo Courtesy Sys-Tech Design)

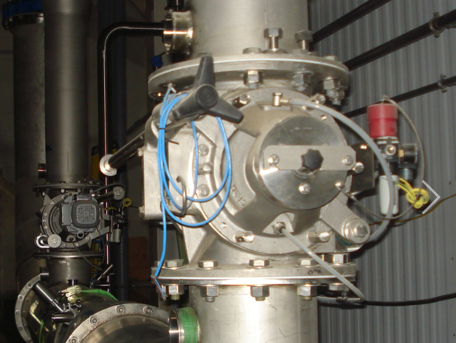

A common suppression technology is the Sodium Bicarbonate suppression system. The suppression and isolation systems consist of bottles which are filled with sodium bicarbonate (baking soda) and nitrogen and pressurized to a high pressure. When the explosion protection system is activated the bottles are triggered by either a microswitch which releases the stored high-pressure sodium bicarbonate into the system by way of a burst disk, or a small explosive charge which is activated and breaks the seal in the bottle allowing the bottle to discharge the suppressant into the system through a hygienic spreader assembly.

Figure 7. Microswitch Suppression Bottles installed on Processing Equipment (Photo Courtesy Sys-Tech Design)

Figure 8. Explosion Charge Suppressant Bottle (Photo Courtesy IEP Technologies)

Figure 9. Rotary Airlock Valve (Photo Courtesy DMN-Westinghouse)

Figure 10. DMN Rotary Airlock Installed on Cyclone Discharge

The explosion protection system is activated by one of two methods. The first method is by pressure detectors. These detectors measure the rate of rise of the pressure in the protected vessel. As an explosion propagates through a system it is proceeded by a pressure wave. The pressure detectors pick up on the increasing pressure and the speed at which the pressure increases. If the system believes that the pressure wave is a spike is caused by an explosion it will activate the suppression and isolation bottles.

The second method is by infrared detection. For systems that are producing products with a low Kst value, a pressure wave proceeding an explosion may travel too slowly to be captured by the pressure detectors. In this case, infrared sensors at the outlet of the dryer or fluid bed dryer and the inlet of the exhaust filtering equipment (cyclones, bag filters, or scrubbers) will sense the light from a flash fire and activate the suppression and isolation system.

Figure 11. Pressure Detector Explosion Protection (Photo Courtesy IEP Technologies)

Dryer Safety – Explosion Protection

The explosion safety system should be designed to adhere to all equipment relevant National Fire Protection Associate requirements for the protection of spray drying and powder processing systems including:

NFPA 652: Standard on Fundamentals of Combustible Dust

NFPA 654: Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids

NFPA 61: Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities

In addition, the deflagration venting system should adhere to:

NFPA 68: Standard on Explosion Protection by Deflagration Venting

And, the explosion suppression system should adhere to:

NFPA 69: Standard on Explosion Prevention Systems

The Spray Drying explosion protection system is just a part of the safety measures that a facility Dust Hazard Analysis as detailed in NFPA 652 may be required to have. While sometimes seen as a nuisance and a maintenance headache without a return on investment, the protection that the systems offer will be invaluable in protecting the investments producers rely on day in and day out and more importantly, protecting the staff of those facilities which form the backbone of the operations.

There is a lot to consider when installing an explosion suppression system. As regulations and customer preferences continue to evolve, it is likely more and more systems will be purchased to follow the regulatory and to protect your assets. Contact us for more information when you are considering installing an explosion suppression system on your spray dryer or for any of your other spray dryer or evaporator needs.