Benefits of Dehumidification of Drying Process Air

GLM Hydro Dryer Problem Solving: –One of the easiest ways to improve stability and increase the capacity of a drying system is through the installation of a dehumidification system for the incoming process air.

Reliable drying of powder requires a stable and consistent airflow and most importantly – predictable moisture content of the drying air. Dryers are designed for a specific mass flow of air to dry the product and this mass flow is determined by the relationship of the moisture content of incoming drying air and exhaust air. Generally, the average relative humidity of the plant location is chosen when designing a dryer. However, the actual relative humidity and consequently the moisture content of the drying air can vary significantly over the year. This variation in air moisture can seriously impact dryer operation and production.

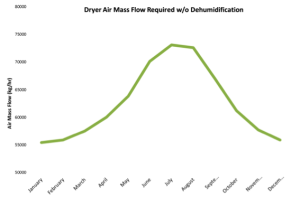

The ambient air conditions drive the evaporative capacity of unconditioned drying air. Figure 1 shows the airflow required as it changes over the course of the year for a recent dryer inquiry in Minnesota. This is based on monthly averages of relative humidity and temperature. As the moisture content of the drying air increases, the exhaust air humidity must be maintained at design levels to prevent stickiness of the product, so it is not advisable to slow the air flows down to allow more evaporation. This will also prevent condensation of water in the exhaust equipment as the exhaust air cools. You also cannot simply increase the airflow through the system as you will alter the residence time of the product, interrupting proper drying of the product. You must be careful about increasing the temperature of the dryer due to the thermoplasticity of many products – at higher temperatures they may begin to stick just as if the moisture content was too high. Additionally, increased temperatures may lead to scorching of the product. In order to maintain product quality at increased inlet humidity, production will have to be reduced.

The ambient air conditions drive the evaporative capacity of unconditioned drying air. Figure 1 shows the airflow required as it changes over the course of the year for a recent dryer inquiry in Minnesota. This is based on monthly averages of relative humidity and temperature. As the moisture content of the drying air increases, the exhaust air humidity must be maintained at design levels to prevent stickiness of the product, so it is not advisable to slow the air flows down to allow more evaporation. This will also prevent condensation of water in the exhaust equipment as the exhaust air cools. You also cannot simply increase the airflow through the system as you will alter the residence time of the product, interrupting proper drying of the product. You must be careful about increasing the temperature of the dryer due to the thermoplasticity of many products – at higher temperatures they may begin to stick just as if the moisture content was too high. Additionally, increased temperatures may lead to scorching of the product. In order to maintain product quality at increased inlet humidity, production will have to be reduced.

The drying airflow required to meet the required powder throughput for the dryer in Minnesota varies 52% throughout the year, which translates into a 37% reduction in designed dryer throughput in order to maintain the design process conditions – outlet air humidity, residence time, water content of the final product, etc. For this particular plant, reducing throughput by 37% to maintain product quality is equal to a loss of 580 kg/hr (1276 lb/hr) of production.

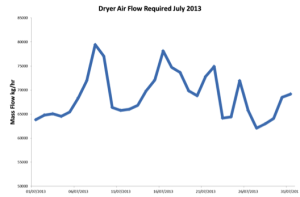

There can also be drastic variation during the course of a single month. Figure 2 shows airflow requirements for the same dryer in Minnesota based on the weather data from July 2013. The required airflow varies 28% in this month alone, which equals a 17% variation in dryer production during the month.

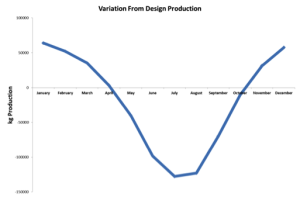

The addition of a dehumidification system can improve yearlong dryer capacity and production stability in existing plants by maintaining drying air moisture content at design levels.  Figure 3 shows the expected variation in monthly production from design over the course of the year. The dryer is expected to perform better than design during the winter months as the moisture content drops during this time of the year. During the summer months, the dryer is expected to perform much worse, canceling out any gains during the winter months. Without a dehumidification system, the dryer in Minnesota is estimated to be short 226 metric tons (249 US tons) a year versus design production. Addition of a dehumidification system to reduce the inlet moisture content of the system by only 2 g of water per kg of air below design is estimated to increase production by 237 metric tons (261 US tons) a year.

Figure 3 shows the expected variation in monthly production from design over the course of the year. The dryer is expected to perform better than design during the winter months as the moisture content drops during this time of the year. During the summer months, the dryer is expected to perform much worse, canceling out any gains during the winter months. Without a dehumidification system, the dryer in Minnesota is estimated to be short 226 metric tons (249 US tons) a year versus design production. Addition of a dehumidification system to reduce the inlet moisture content of the system by only 2 g of water per kg of air below design is estimated to increase production by 237 metric tons (261 US tons) a year.

If a dehumidification system is part of the design of the dryer from conception it can significantly reduce the physical footprint of the dryer. If the dryer from Minnesota was designed to meet the design production year-round, it would have to be sized for the worst ambient conditions in mid-summer. Addition of dehumidification in the design phase reduces dryer size by 25% while maintaining the same production.

Whether in new plant construction or for existing retrofits, the addition of a dehumidification system can provide significant improvements in stability and reliability of your dryer.

Contact us for this or any other inquiries.