Demystifying Dehumidification and Drying Part 3: Cooling vs. Desiccant Dehumidification

- Posted on 20th July 2021

- in Dehumidification, Dryers

- by John Real

Welcome back to Part 3 of our “as-of-yet undetermined number of parts” series on Dehumidification in Dryers! If you missed Parts 1 and 2, where we discuss why you would want to consider dehumidification in dryers and our primer on the most important things to know about psychrometrics, click here for Part 1 or here for Part 2.

Welcome back to Part 3 of our “as-of-yet undetermined number of parts” series on Dehumidification in Dryers! If you missed Parts 1 and 2, where we discuss why you would want to consider dehumidification in dryers and our primer on the most important things to know about psychrometrics, click here for Part 1 or here for Part 2.

Part 3 is all about the two main types of dehumidification we encounter in the drying world – cooling-based dehumidification and desiccant-based dehumidification. While both processes achieve dehumidification, the way they go about it is completely different, and as with anything else in engineering, each has its pros and cons.

Cooling Based Dehumidification

Cooling-based dehumidification is dehumidification based, you guessed it, on cooling the air down. When air is cooled below its dewpoint temperature, moisture will condense out of the air onto the nearest surface. The air has been dehumidified by the process of cooling and then condensation. The amount of moisture that can be removed depends on how cold the air can be cooled. The lower the temperature you can make the air, the more moisture that can be removed from the air and the drier the air will become.

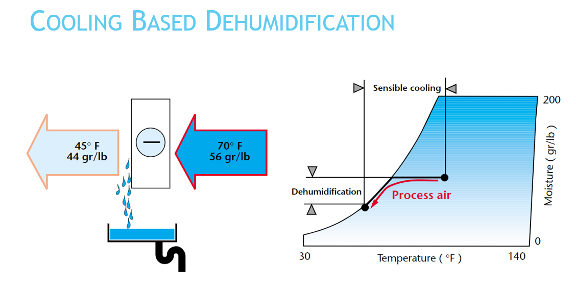

On the psychrometric chart, this process is plotted by cooling the air from its starting temperature and relative humidity and moving left on the chart until you reach the saturation line or 100% relative humidity. Once you hit the saturation line, any additional cooling will remove moisture from the air, dehumidifying it.

Figure 1. Cooling Based Dehumidification. Image courtesy Munters Corp.

In the example above, we start with air at conditions 70°F and 50% relative humidity. When cooling the air from 70°F to 51°F, no moisture has been removed, but the air has become saturated, and the relative humidity is now 100%. If the air is cooled further, moisture will begin to condense out of the air. If we cool the air from 51°F to 45°F, we will remove 12 grains of moisture through condensation.

Cooling-based dehumidification systems can dehumidify air efficiently at higher temperatures that are at or above freezing. Special precautions are necessary when using cooling systems to dry air below a 40°F dewpoint to prevent the moisture that is being removed from the air stream from freezing to the coil surfaces.

Desiccant Based Dehumidification

Desiccant-based dehumidification is very different from cooling-based dehumidification. Instead of cooling the air to condense the moisture, the desiccant material attracts moisture from the air by creating an area of low vapor pressure at the surface of the desiccant. The pressure exerted by the water is higher in the air than at the surface of the desiccant, and so the water molecules move from the air to the desiccant, and the air is dehumidified.

This low vapor pressure is the essential characteristic of desiccants. When a desiccant is cool and dry, its surface vapor pressure is very low, and it can attract moisture from the air. After the desiccant becomes wet and hot, its vapor pressure becomes very high, and it will give off water vapor to the surrounding air. Water vapor moves from the air to the desiccant and back again based on the vapor pressure differences.

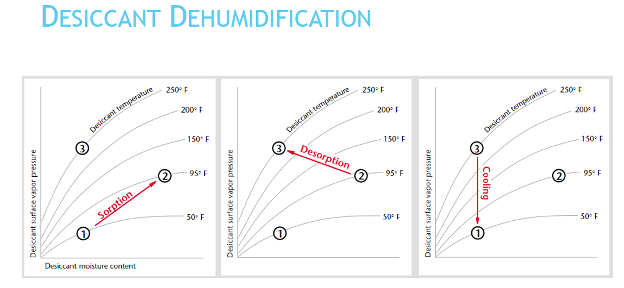

Figure 2. Desiccant Based Dehumidification. Image courtesy Munters Corp.

Desiccant dehumidifiers make use of changing vapor pressures to dry air continuously in a repeating cycle described by the image above. The cycle begins at point one when the desiccant is dry and cool, and its vapor pressure is very low. This low vapor pressure causes the moisture vapor in the air to move from the air to the surface of the desiccant. As the desiccant surface moisture increases, the adsorption process causes the temperature to rise with the vapor pressure. At point two, the vapor pressure of the desiccant is equal to that of the surrounding air, and the desiccant is moist and warm.

At this point, the desiccant can no longer absorb moisture because there is no pressure difference between the desiccant surface and the surrounding air. The desiccant is now moved out of the air stream and then heated. Increasing the temperature of the desiccant increases its vapor pressure, which becomes much higher, and the desiccant is placed into a new airstream.

The desiccant surface vapor pressure is now very high, much higher than the surrounding air. Moisture moves off the surface to the air to equalize the pressure differential. At point three, the desiccant is dry, but since it is hot, its vapor pressure is still too high to collect moisture from the air. To restore its low vapor pressure, the desiccant is cooled – returning to point one in the diagram ready to collect more moisture.

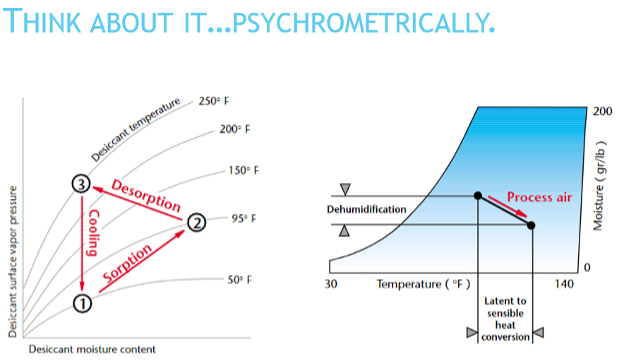

Figure 3. Desiccant and Psychrometrics. Image courtesy Munters Corp.

When moisture is removed from air, the reaction liberates heat. This is simply the reverse of evaporation; when water is evaporated, heat energy is consumed by the reaction. In cooling-based dehumidification, the heating effect of dehumidification is less apparent because the heat is removed immediately by the cooling coil. In a desiccant dehumidification system, the heat is transferred to the air and the desiccant, so the process air generally leaves the dehumidifier warmer than when it entered the desiccant unit. As moisture is removed from the air, its enthalpy stays constant, so its sensible temperature rises.

The temperature rise is directly proportional to the amount of moisture removed from the air – the drier the air leaves the dehumidifier, the warmer it will be.

Which Way to Go?

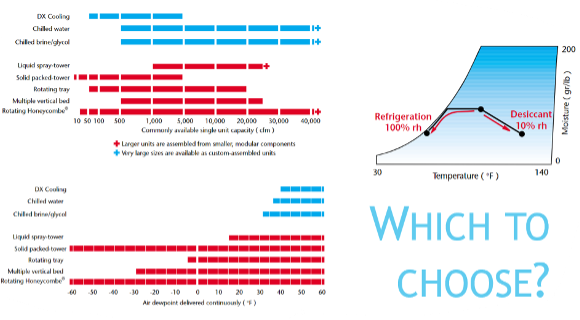

Figure 4. Cooling or Desiccant – Which will you choose? Image courtesy of Munters Corp.

Choosing between cooling and desiccant dehumidification is just like anything else in life – a little fuzzy, gray, and entirely dependent on the desires and the application.

In terms of airflow capacity in a single unit, cooling dehumidification is more capable than just about any desiccant technology other than perhaps the wheel desiccant.

Cooling and desiccant are also complementary technologies. Cooling dehumidification is very efficient at drying large airflows to saturation, and desiccant is efficient at bringing saturated air to very low dewpoints.

Be sure to join us for Part Four in this series, in which we finally apply these technologies to drying applications!

Contact us for more information if you would like to know if dehumidification can work for your process or for any other drying, evaporation, and thermal heat treatment questions.

Tags: Dehumidification, Dryer, Dryers, Powder production